The 3rd year: Fabrication facilities for space payloads. 太空酬載製作設備。

- Build data acquisition system for space payloads: The system is connected with in-house plasma instrument to be a standard instruments and to test the future payloads. Using the system, we can develop the payload prototype rapidly and find out suitable measurement parameters, etc. A residual gas analyzer has also been installed to enhance the monitoring system.

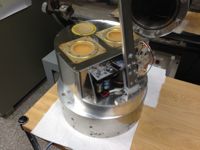

加強太空電漿環境量測能力: 此量測系統與自製的電漿量測儀器相連接,作為太空電漿模擬艙的測量標準與測試未來酬載之用。利用此套系統,可快速開發酬載原型,找出適合量測之酬載參數等。添購氣體監控裝置,可觀測太空電漿模擬艙內的氣體成份的使用狀態。 - Purchase PCB rapid prototyping and SMT equipments: A PCB plotter, a through-hole plating system, a bench-top multilayer press, a screen printing and solder-resist masks printing, a SMT solder paste printer, a pick and place assembly system, a lead-free reflow oven, etc. have been purchased for space-grade PCB fabrication.

購買太空酬載電路製作之設備: 高精度之電路板雕刻機,電路多層板與表面焊接等設備。以期建立符合太空規格的電路板自行製作技術。 - Apply for scientific payload mission on Sounding Rocket IX: We have obtained the scientific payload mission on Sounding Rocket IX to perform in-situ ionospheric observation on E-region plasma irregularities with our own payload fabricated in space payload laboratory. We will install a space plasma sensor package (an impedance probe, a planner Langmuir probe, a retarding potential analyzer, and an aspectmeter module) onboard the Sounding Rocket IX.

申請探空九號科學酬載任務: 向國家太空中心申請次軌道與衛星科學酬載任務,安裝自行設計與製作的電漿量測酬載。